SEGMENTAL CONCRETE BRIDGE BONDING

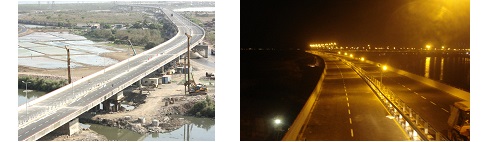

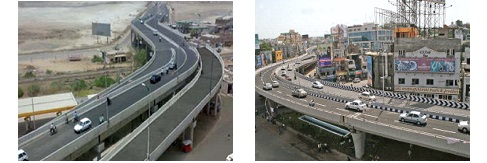

FAIRMATE supplied the concrete admixtures and other products for the precast and insitu concrete works on this structure, and now we develop a high strength epoxy resin adhesive system, to bond the joints between the precast concrete segments.

The Successful combination of new pre-stressing systems with new assembly equipment led to the development of the precast segmental construction method for bridges. The most important first developments were probably in 1940s, and it is now used by many of engineers, contractors, equipment producers and manufacturers around the world. It has become established and used successfully on numerous large projects, including many of the world’s most important recent bridge structures.

FAIRBOND CS PRODUCTS – SEGMENTAL BRIDGE BONDING

FAIRBOND CS (S) & FAIRBOND CS (W) has been used extensively for a segmental bridge bonding construction applications, the need became clear for a specific range of segmental bridge adhesive which could meet the different and increasingly precise requirements of bridge designs and at the different working temperatures which occur during their construction periods. These included application in daytime temperatures of up to 45°C, curing during very low and cold night time temperatures, plus the rapid erection cycles demanded for the precast segments.

The FAIRBOND CS (S) & FAIRBOND CS (W) were the result – a range of adhesives, optimized for the specific technical requirements, suitable for use on the most challenging bridge projects. This is based on a reactive hardening epoxy binder system, with optimized filler granulometries, so that the products support the continuously optimized production process of segmental bridge construction.

The Fairbond CS (S) & Fairbond CS (W) (segmental bridge adhesive) range, which fully complies with FIP and AASTHO standards, but also to be able to meet the specific requirements of each construction site.

The application and characteristics of segmental bridge bonding products must be carefully matched so that the adhesive can meet the following requirements:

• To bond the surfaces so that compressive and shear forces also the tensile forces can be safely convey from to every bridge segment.

• To lubricate the joint faces between the segments to make them easier to finally position together during their installation.

• To seal the joints between the segments against future ingress of water and de-icing salts etc,i.e. to protect the prestressing cables against corrosion.

THE PERFORMANCE REQUIREMENTS

In order to meet all these requirements under the different site application conditions, including variable temperatures/ moisture contents/ mixing and application methods etc., the epoxy adhesive must have carefully selected precisely defined characteristics and test methods to confirm these.

The table below contains the main criteria covered by “International Federation of Prestressing” FIP (now developed as fib “Federation international de beton) and AASTHO (American Association Of State Highway and Transportation Officials), which have also shown the FAIRBOND CS products specification.

EPOXY JOINTING ADHESIVE

Purposes of Epoxy

The purposes of using an epoxy resin in the joint between the segments are:

• To maintain the structural integrity of the joint and maintain a monolithic concrete segment

• To completely fill any minor surface imperfections and irregularities between the match cast surfaces

• To provide a water and grout tight seal, preventing chloride intrusion

• To act as a lubricant when erecting the segment

• To ensure tight fit between the segments so that the compressive and shear stresses are transmitted directly across the joint

TYPES AND APPLICATION OF EPOXY

Epoxy comes in two part compounds consisting of a resin and hardener. When mixed together, they begin curing which can take anywhere from a few minute to a few hours, depending on the formulation, the site and storage temperature and the mass of the epoxy, The cure time will be shorter when epoxies are mixed in higher temperature conditions and in larger masses.

Segmental bridge epoxies are specially formulated as either normal or slow setting resins. For Segment by segment erection, the normal set epoxies are used and for span by span erection, the slow set epoxies are used. It is important to use the correct pot life and correct temperature range to ensure good working time and proper strength gain of the epoxy.

Surface preparation:

Concrete should be mechanically sound and free form contamination such free water, mould oil, grease, laitance or dust. A dry grit blasting on the surface is recommended for optimum adhesion. Sections to be checked for good alignment. A ‘dry run’ before the first application of the adhesive is recommended to ensure correct timing.

Mixing:

The contents of hardener should be added in to the base and mixed for 2-3 minutes with a paddle attached slow speed heavy duty drill. It should be ensured that the sides and base of the can is thoroughly scrapped down. A uniform grey colour should be obtained after homogenous mixing.

Application:

The mixed adhesive should be applied at required thickness to both laying surfaces with a serrate trowel or other suitable spreader. The joint should be closed immediately. If this is not achieved the surface of the adhesive should be slightly scratched immediately prior to closing the joint to be exposed fresh adhesive. The joint must be closed within the open time of the adhesive. On site monitoring of the operation using lapped asbestos cement panels is recommended.

When the segments are brought together and stressed, excess epoxy is squeezed out. For joints over traffic or water, procedures must be implemented to avoid dropping below. Once the segments has been joined and stressed, all excess epoxy should be cleaned. If leaving it to harden will make it more difficult to remove later on.

Cleaning:

Tools and equipment should be using SAFECORE TOOL CLEANER immediate after use.

SHELF LIFE AND STORAGE

FAIRBOND CS (W) & FAIRBOND CS (S) will have a shelf life of 12 months in un-opened containers when kept in dry conditions at a temperature 5 0c to 30 0c. Storage at higher temperature or high humidity may reduce the shelf life.

HEALTH AND SAFETY

FAIRBOND CS (W) & FAIRBOND CS (S) is non-flammable. However, it should not come in contact with skin and eyes. If accidental skin contact occurs, remove immediately by washing with soap and water – Do not use solvent. In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. Avoid inhalation of vapors and ensure adequate ventilation. Wear suitable protective clothing, gloves and eye/face protection. Barrier creams provide additional skin protection. If swallowed seek medical attention immediately. Do not induce vomiting. For further information see SAFECORE Safety Data sheet.

QUALITY ASSURANCE

Fairmate manufactures entire range of construction chemicals under compliance of ISO 9001, ISO (EMS) 14001 & OHSAS 18001 (Occupational Health and Safety) certified by ISOQAR / UK.

TECHNICAL SERVICES

While new advances and changes will take place but one thing will never change is quality and meeting special needs of our customers. Our laboratory in Baroda and technical personnel & experts are available to provide additional information and technical assistance. We are eager to work with you in development of new product and resolve your problem.