INTEGRAL WATERPROOFING ADDITIVE FOR CONCRETE AND PLASTER

Water leakage and seepage is the enemy of all structures. It is important to build correctly with due attention to water proofing of basements, exterior walls, roofs and building watertight pipelines. Large numbers of structures lack proper implementation and thereby have less life. If water enters and starts damaging any part of the structure, early repair action must be taken. For excessive damaged structure restoration may be possible by use of repair chemicals after ensuring structural safety.

We realize there is a need to provide building professionals with suitable specialized information to enable them to ensure higher life of all structures. FAIRMATE CHEMICALS PVT. LTD. is a step in that direction. In the developed countries, use of Construction Chemicals is quite extensive. India has to catch up with high growth rates in this field.

Leakage is a common problem in any home or structure, caused either by the age of the structure, or improper

construction and design methods. Some of the most common reasons for water leakage in structures are elaborated below:

1.Construction Practices

• Untrained man power

• Improper preparation of mortar and concrete mixes

• Use of excess water for to make mixes easily workable, which results in porous concrete, inviting leakage.

• Bleeding & segregation in concrete resulting in honey combing/voids

• Inappropriate compaction/vibration of concrete

• Inadequate curing in early and later stages

• Negligence in site supervision.

2.Inappropriate Material Selection

Enough care is not taken in specifying the correct construction materials such as :

• Right quality & grade of cement depending on service requirements

• Good quality crushed aggregates of various sizes depending on mix proportion

• Sand free from silt and other chemicals

• Potable water, i.e. water should not contain any chlorides, etc.

• Other chemical and mineral additives that can increase the durability of construction

3.Aggressive Climatic Conditions

Environment plays an important role in determining the durability of any structure. More aggressive the climate, more stringent is the precautions to be taken. Structures which are exposed to marine regions or situated in polluting industrial belts, are more prone to chemical attack.

4.Mechanical Damage

Concrete structures are not often used only for the purpose they have been designed, but subjected to forces such as excessive loading, impact, abrasion and other mechanical damages. As a result, structural cracks develop in slabs. These too contribute to the problem.

5.Inadequate Maintenance

Problems like cracks, dampness, etc. are neglected in the initial stages and timely corrective measures are not undertaken, ultimately leading to deterioration of the structure. It is advisable to undertake preventive maintenance and carry out timely repairs through a competent contractor, the correct specification for materials and methods, depending upon the problem.

Diagnosing the root cause of the problem is vital. Only then a suitable solution can be arrived.

The treatment will then be cost effective from the long term point of view. Repair or maintenance must be done

systematically as under:

Visual inspection

Non destructive testing as advised by a consultant or an expert, if required Once the diagnosis is done, a proper scheme can be made to undertake repair and rehabilitation work using suitable materials aided by construction chemicals.

Benefits

• Ensures perfect watertight structure

• Reduces water penetration

• Reduces mortar dropping , when used in plaster.

• Reduces CO2 attack.

• Contains no flammable ingredients and is non corrosive.

• Very low cost

• Increase plasticity of concrete, thus it flows easily without increase in water and better compaction is achieved.

• Does not affecting the setting time of the concrete and mortar.

• Becomes an integral part of the concrete.

• Reduces efflorescence.

Description

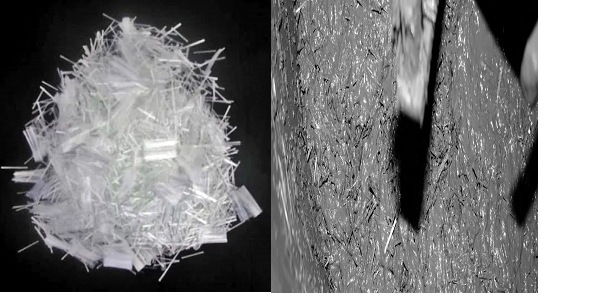

FAIRCRETE RMW is an integral, high performance waterproofing additive is based on high performance polymers, which reduces the permeability throughout the depth of concrete. It confirms to IS 2645 – 2003. FAIRCRETE RMW is approved by Bureau of Indian Standard vide ISI registration no.CM/L7648592.

FAIRCRETE RMW is unique liquid waterproofing additive for concrete. It consists of a water based suspension of inorganic waterproofing agents in a solution of various polymers and is added to the concrete during the batching process or in a ready-mix truck with full mixing capabilities. In addition to its water proofing characteristics FAIRCRETE RMW also significantly increases the compressive strength and freeze-thaw resistance of concrete and acts as a super plasticizer.

USES

FAIRCRETE RMW is used to minimize permeability and porosity of concrete and cement sand mortar. Useful product for water retaining structures like terrace, chajjas, water tanks, parapets, bathroom, toilets and industrial structures like reservoirs, cooling tower etc.,

APPLICATION

Plaster : FAIRCRETE RMW is ideal for use with all sand and cement mortars where it is required to reduce permeability to a minimum.

Concrete : FAIRCRETE RMW is recommended for all general concrete work where the risk of porosity and permeability must be minimised. Eg. basements, bund walls, tanks, balcony, floor and roof slabs.

The required quantity of FAIRCRETE RMW is measured and poured with the regular pouring of water in case of conventional concreting. Separate dispensing system is required for RMC plants.

FAIRCRETE RMW water mixture shall be added to the concrete or mortar and mixed thoroughly. Mixing shall be continued and further water shall be added until the required workability is obtained. The total amount of water added per mix in the initial batches shall be maintained for the remaining batches.

PACKING & DOSAGE

FAIRCRETE RMW can be added in 150-200ml per bag of cement. Optimum dosage is 150ml/50 kg. cement.

FAIRCRETE RMW is supplied in 150ml, 500ml, 1, 5, 10, 50, 100, 200 ltr. carboys.