EPOAQUA SL

Is it possible to have a water vapour permeable system which gives excellent waterproofing to the substrate?

Yes absolutely, Our EPOAQUA SL product is water based epoxy, water vapour permeable system.

It is known that concrete surface has some water which does not bond with the cement and is later evaporated due to the hydration process. The pores that remains intact after this water is evaporated or after the hardening of concrete can collect water again due to various reasons such as poor plumbing or soil moisture content or even rain fall etc. This collected water is again evaporated due to the equilibrium reached with the exposed surrounding. This process of achieving equilibrium will rather continue if there is increase or decrease in relative humidity of the ambient air.

This situation of moisture content present in pours when try to escape after the coating is applied can cause bubbles on the surface before hardening. It can also reduce adhesion of the coating to the substrate. To avoid these situations to occur it is required that the floor topping allows the surface to breathe and allow easy evaporation of the water vapour from the substrate but at the same time protect the substrate from liquid water.

Such flooring system can be effective on humid substrates. These floorings due to its ability to allow the substrates to breath can help it to have

PRODUCT

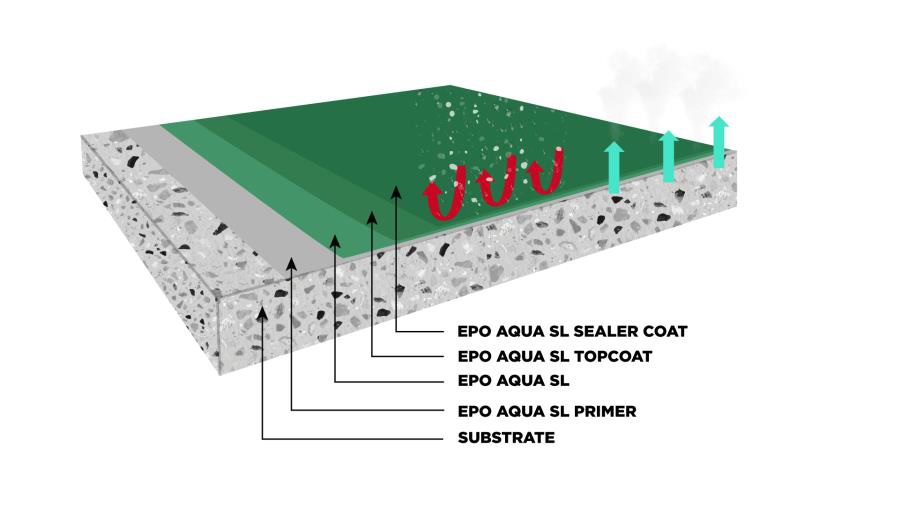

EPOAQUA SL is a water vapour permeable epoxy advanced resin based flooring system. It is a complete system in itself, having low odour, low emission, hard-wearing, water-proofing surface with good mechanical and chemical properties. It is available in a wide colour range. The ideal thickness of the layer is between 2mm to 4mm.

EPOAQUA SL is very economic product and can be applied very easily. The system consist of Primer, Base Coat, Top coat and Sealer coat of the same series.

Firstly it is required to prepare the surface before application of primer. The surface must be free from any kind of contamination such as oil, grease, surface treatment, and coatings etc. The surface must be mechanically prepared for proper gripping and any kind of holes or voids shall be fully exposed. Any kind of loose material or dust can be removed using a brush or vacuum.

EPOAQUA SL PRIMER shall be applied using a brush, roller or airless spray. It is available in two components base and hardener which is required to be mechanically mixed for a minimum of 3 minutes before application.

Next apply EPOAQUA SL BASE COAT which is a three component material containing base, hardener and aggregates. The base coat is applied by spreading the mixed material in desired thickness evenly using a notch trowel.

Apply EPOAQUA SL TOP COAT a two component material consisting base and hardener. It is mixed well and spread evenly in required thickness using a notch trowel.

Apply EPOAQUA SL SEALER COAT after the top coat. It is a two component material which is mixed properly using mechanical method and applied using a brush or a roller.

The above mentioned system is essential to be followed to achieve the water vapour permeable flooring.

SALIENT FEATURES:

High water vapour permeability

Low emission, complies with green environmental requirements

Prevents osmotic blistering of resin based coatings over damp substrates

Economical and fast, easy application

Good self levelling properties and joint less

Frost and de-icing salt resistant

Good abrasion & chemical resistance

Hygienic, non-porous and liquid tight

Thermal expansion properties similar to concrete

Excellent bond to green or hardened concrete whether damp or dry

Excellent early and final mechanical strengths

Excellent resistance to water and oils

Contains no solvents, VOC free

Available in wide range of colours

Very good colour stability(indoor)