Blog

Introducing FAIRFIX EPU: Your Ultimate Bonding Solution

In the world of adhesives, where strength, versatility, and innovation intersect, emerges the exceptional FAIRFIX EPU. This adhesive marvel takes the best of both worlds – epoxy and polyurethane – and blends them into a formidable bonding solution. So let’s take a closer look at what sets FAIRFIX EPU apart, while keeping its remarkable applications and benefits intact.

Discovering FAIRFIX EPU:

FAIRFIX EPU isn’t your ordinary adhesive; it’s a fusion of two adhesive powerhouses, epoxy and polyurethane. Epoxy provides unmatched bonding strength and resistance to chemicals, while polyurethane adds flexibility and the remarkable ability to adhere to a wide spectrum of materials.

Unveiling Its Power: Where It Excels: FAIRFIX EPU’s strength shines across various application domains:

1. Construction Brilliance: It’s your go-to adhesive for securely bonding cement surfaces, drywall boards, both interior and exterior walls, and even floors – offering a solid foundation for architectural excellence.

2. Metal Fusion Expertise: When dealing with metals like iron, steel, and more, FAIRFIX EPU forges unbreakable connections, making it an essential tool for structural and artistic metalwork.

3. Concrete Confidence: As a combination of epoxy and polyurethane, it forms strong connections with both plain and reinforced concrete, making structures even stronger.

4. Versatility at Its Finest: Its impressive compatibility extends to a wide range of surfaces – from rubber and glass to wood and beyond – making it an adhesive of choice for various bonding scenarios.

Outstanding Advantages: The great qualities of FAIRFIX EPU keep on shining:

1. Strength Redefined: Merging the strength of epoxy and polyurethane, it creates strong, long-lasting bonds.

2. Flexibility and Toughness Combined: Stays tough yet flexible to accommodate movements without compromising the bond.

3. Unparalleled Versatility: Be it indoor or outdoor applications, on diverse surfaces like concrete or wood, FAIRFIX EPU adapts effortlessly.

4. Reliability in Concrete Bonding: When working with concrete, trust FAIRFIX EPU to enhance structural integrity and longevity.

5. Innovation Personified: FAIRFIX EPU showcases the amazing results from combining two powerful adhesives.

FAIRCRETE W

CHLORIDE BASED ACCELERATING PLASTICISER

Accelerating admixtures affect the rates of reactions between cement and water to give an overall increase in the hydration rate. Thus, the use of accelerators in concrete provides a shortening of setting time and/or an increase in early strength development.

FAIRCRETE W is Chloride based plasticiser for Accelerating the setting time of plain cement concrete for early development of strength. It is ideal for providing increased resistance to frost damage during and after construction of hollow blocks.

SALIENT FEATURES OF FAIRCRETE W,

• Increases the rate of strength development.

• Increases density.

• Accelerates the hardening of floors and screeds.

• Accelerates the setting time of concrete.

• Resistant to freezing in cold weather concreting.

• Can be used for P.C.C. Work.

• Ideal for hollow blocks and concrete bricks.

• Allows continue placing of concrete at low temperature.

HOW TO MIX,

FAIRCRETE W should be directly added to the mix preferably with the mixing water. The optimum dosage rate should be determined by site trials.

FAIRCRETE W can be used,

• Resist the effect of frost.

• Increase the rate of strength development.

• Concreting can be done in cold weather, Mass concreting under seawater, and concrete hollow block manufacturing.

DOSAGE & PACKING

• 600 ml to 1000 ml per 50 kg of cement.

• 1,5,10,50,100ltr. carboys.

FAIRPLAST IP

WATERPROOF PLASTER ADDITIVE

FAIRPLAST IP is high workable mortar plasticizer cum waterproof plaster additive in powder form which should be dry mixed in a mortar. It gives better consistency, prolonged workability, and smooth & creamy mortar even with harsh sand. It introduces air into the mortar in the form of extremely fine and evenly dispersed bubbles. This entrained air imparts improved workability which, due to the stability of the tiny bubbles, prevents premature stiffening and avoids the need for repeated “knocking up”.

The hardened mortar bubbles provide a cautionary effect in screeds or renders. Capillary channels are also made discontinuous by the formation of bubbles, thus reducing the penetration of water.

SALIENT FEATURS OF FAIRPLAST IP,

• Prolonged workability, ease to handle mortar.

• Easier spreading of mortar and easy placing of bricks and blocks

• Reduces mortar droppings from surface

• Greater resistance to frost damage during construction

• Protection against freeze-thaw damage after construction

• Reduces permeability hence ensures waterproof plaster

• Increases yield of mortar results into cost benefits

• Reduces drying shrinkage cracks.

• Chloride free and hence no risk of corrosion.

FAIRPLAST IP is suitable for use with sand/cement plaster where it is required to reduce permeability. It can also be used in external plastering of roof and balcony screeds, plastering of basements and tanks, and external masonry walls.

HOW TO MIX:

Measure required quantity of sand, aggregate with cement. Then sprinkle proper amount of FAIRPLAST IP over the cement. Mix properly and then add required quantity of water to it.

PACKING & DOSAGE

200gms pouch, 1 kg pouch, 5kg, 25kg HDPE bags.

Dosage: 200gms per 50 kg cement.

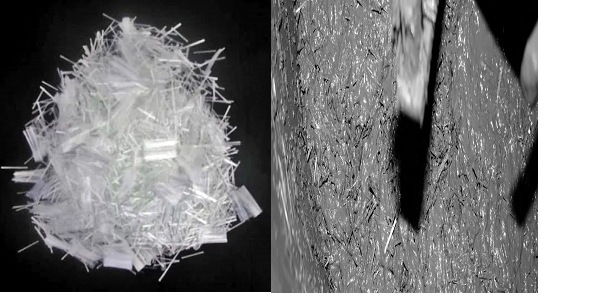

FAIRFIBRE

FIBRE REINFORCEMENT FOR CONCRETE AND MORTAR

Fiber-reinforcement concrete and mortar are ideal for improving the durability and toughness performance of concrete and mortar. Fibers in concrete help reduce shrinkage cracks, increase strength, and increase energy absorption. FAIRFIBRE is a unique specially treated chemically inert fiber reinforcement for concrete and mortar which instantly disperses into the mix.

FAIRFIBRE is recommended where the objective is to control temperature/shrinkage cracking while improving basic durability. Also, it improves the tensile and compressive strength of concrete and mortar, minimizes cracks, and reduces permeability in the mix. It reduces the rate of heat evolution, spreading heat of hydration over a longer period & reducing thermal cracking effects. FAIRFIBRE is non-toxic and non-flammable.

FAIRFIBRE is easily and instantly disperses in to the mix. It reduces permeability hence ensures water tightness & reduces density & ensures more yield of mix & also reduces number of construction joints in floor.

SALIENT FEATURS OF FAIRFIBRE,

There are multiple reasons for adding fibers in concrete,

• Improves tensile and compressive strength

• Arrest drying shrinkage cracks

• Minimises steel reinforcement in industrial floors

• Improves durability

• Free from corrosive substances.

• Good resistance to impact and abrasion.

• Increases fatigue resistance & toughness.

• Non-corrosive, non-magnetic, chemically inert and 100% alkali proof so no reaction with aggregate and cement alkalies

It can be used for internal plaster, External plaster, Concrete repairs, Terrace slab, driveways, sidewalks, Industrial floors, Concrete roads, precast concrete, railway sleepers etc.

PACKING & DOSAGE

For optimum performance 125gms pack should be used with 50 kg. of cement. Generally it should be used 0.2% to 0.6% by weight of cement depending on the required performance. FAIRFIBRE is supplied in 125gms & 900gms pack

FAIRFIBRE P

POLYESTERFIBRE REINFORCEMENT FOR CONCRETE AND MORTAR

Normally concrete structures have high compressive strength but low tensile strength. Polyester fiber increases the properties of concrete such as compressive strength, tensile strength, impact strength & abrasion resistance. Fibers provide support to concrete in all directions by equally distributing throughout the matrix. It also prevents the problem of corrosion.

FAIRFIBRE P is a specially designed polyester fiber that instantly disperses out through the mix and improves and increases the compressive & tensile strength of concrete and mortar. It highly improves the durability of the structure and prevents the shrinkage cracks which are developed during curing making the concrete structure and plaster stronger. It prevents moisture from entering through out the concrete and mortar structures. FAIRFIBRE P also works as a secondary reinforcement in concrete.

SALIENT FEATURES,

• Prevents shrinkage cracks

• Improves tensile and compressive strength

• Reduces water permeability

• Helps prevent the corrosion of steel for primary reinforcement of concrete and mortar

• Improves life of structure

• Reduces density ensures more yield of mix.

• Minimises steel reinforcement in industrial floors

• Cost effective

• Environmental friendly

• Non-hazardous

• Disperses and separates in the dry ready mix easily

• Economical

• Increases flexibility of concrete

It is used for Concrete blocks, Railway sleeper, Roads & pavements, Bridges & dams. It is also use for Slabs, Footings, Foundation, walls and tanks, Manhole covers & tiles etc., PCC & RCC plastering, Pipes & beams.

PACKING & DOSAGE

FAIRFIBRE P is supplied in 125 gms pack. The addition rate of FAIRFIBRE P varies with grade of concrete and mortar. For optimum performance 125 gms pack should be used with 50 kg. of cement.

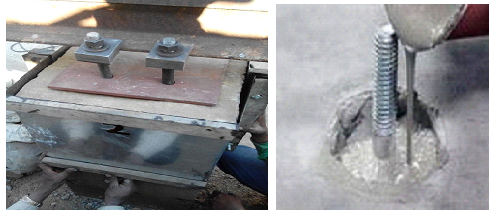

ANCHORGROUT

HIGH STRENGTH, THIXOTROPIC, POLYESTER GROUT

ANCHORGROUT is two components, thixotropic, polyester resin-based anchor grout. When mixed two components it gives high strength, fast setting and fast curing grout of thixotropic consistency. Designed for the anchoring of steel bars and bolts into concrete, machinery and brickwork where speed of installation and early load bearing capacity is required. The cured ANCHORGROUT is resistant to water, oils, petrol greases and mild acids and alkali solutions. ANCHORGROUT permits the production of anchors capable of high loadings.

SALIENT FEATURES

• Rapid strength gain

• Vibration resistant

• Corrosion resistant

• High early strength

• Extremely durable

• Weather resistant

APPLICATION PROCEDURE

Preparation: Hole should be formed using rotary percussive drilling techniques. Diamond drilled holes should be scrabbled. Pre-cast holes should have roughened sides. All dust and drilling debris should be removed. Bars and bolts should be degreased and all rust should be removed.

Mixing: ANCHORGROUT is supplied in pre-weighted two packs. The content of plastic bag should be emptied in metal container, mixed thoroughly to form a smooth paste. Once mixed two components use it in one operation.

Installation: The grout should be injected to the bottom of the hole to avoid entrapment of air. Due to its thixotropic nature, loss of ANCHORGROUT from the hole will be insignificant.

ANCHORGROUT can be used for a permanent installation of reinforcement doweling and starter bars, foundation bolts, base plates, hand rails, safety fences, wall tiles, railway tracks, tie back anchors and grout for tower cranes.

Due to its thixotropic nature it can be used in vertical, horizontal and overhead situations. It can be used in damp conditions. Ideal product for hole grouting having diameter max 25mm & min. 4mm.

PACKING

ANCHORGROUT is supplied in1 Kg

FLOWGROUT 60

ULTRA HIGH STRENGTH, FREE FLOWING, NON-SHRINK CEMENTITIOUS GROUT

FLOWGROUT 60 is based on specially processed cement containing fillers and additives. FLOWGROUT 60 is supplied as ready-to-use grout requiring the addition of a precise quantity of water at the site (3.750 to 4 Litre/25 Kg Grout). FLOWGROUT 60 is suitable for gap widths of between 10mm – 50mm. For thickness over 50mm. (say 75-100), cleaned washed 10mm aggregates can be incorporated at the rate of 20% of the quantity of grout used. This reduces the heat of hydration.

Expansion: Controlled expansion occurs in the unset material to ensure that the grout, when cured will continue to occupy its original volume within the confines of the voids in which it was placed. For thicker sections, it is necessary to fill out the grout with well-graded silt free aggregate to minimize heat buildup.

SALIENT FEATURES

• Prepacked, factory controlled consistent material needing only addition of water

• Shrinkage offset by expansion to ensure original volume is retained

• Free flowing, self-leveling grout

• Can withstand temperature up to 200ºC

• Easy placement and filling of underbases of machinery

• Non-metallic, non-toxic and chloride free

• Holds up to industrial machinery vibration & impact

• Extended work time for easy placement

• Excellent adhesion to concrete and steel

• Non staining

• High ultimate strength and durability

APPLICATION PROCEDURE

Surface Preparation:

• All contaminated surfaces must be cleaned thoroughly by chemical or mechanical methods.

• All bolt pockets and under bases must be free from dust, laitance, and of sound substrate. If needed, substrate with water to allow for full absorption for at least 24 hours.

• Just before the grouting is to commence, all water must be removed completely leaving the surface only damp.

Mixing: Mechanical mixing using a grout mixer or concrete mixer is recommended.

• Place 80% of the water required in a concrete mixer (100% water in case of a grout mixer).

• Slowly add the required amount of FLOWGROUT 60 while mixing continuously for 1 minute. Add balance quantity of water (20%) and mix for 3 to 5 minutes. This will provide a smooth even consistency of grout.

Bolt Packets:

• Depending on the size of the bolt pockets, 50- 100% cleaned 10mm sound aggregates by weight of grout consumption may be sealed incorporated to economies on grout and also to keep the heat of hydration low.

Under base Plate:

• Leak proof strong formwork must be provided to withstand operational stresses while grouting and all edges must be sealed with FLOWGROUT 60 troweling consistency to arrest the grout flowing out of formwork.

CURING:

• 3-4 hours after grouting, all exposed areas must be cured with wet hessian cloths (keep wet always) or water ponding wherever possible for minimum 7 days.

FLOWGROUT 60 can be used to Bolt pockets and base plate grouting of all equipment, Crane, stanchion bases and all types of machinery with dynamic load.

PACKING

FLOWGROUT 60 is supplied in 25 Kg. lined HDPE bag

FLOWGROUT 40

HIGH STRENGTH, FREE FLOW, NON-SHRINK GROUT

FLOWROUT 40 is a single pack ready use, high-strength, free-flowing and non-shrink grout.

FLOWGROUT 40 is based on specially processed types of cement containing fillers and additives. FLOWGROUT 40 is supply as ready-to-use grout requiring the addition of a precise quantity of water at the site (4.75 Litre/25 Kg grout).

Expansion: Controlled expansion occurs in the unset material to ensure that the grout, when cured will continue occupy its original volume within the confines of the voids in which it was placed. FLOWGROUT 40 is suitable for gap widths between 10mm-50mm. For widths, less than 10mm FLOWGROUT EP resin grout can be used. For thickness above 50mm. (say 75-100), cleaned washed 10mm aggregates can be incorporated at the rate of 50%-100% of the quantity of grout used. Water needs to be precisely measured for good early & final strength.

SALIENT FEATURES

• Material shrinkage is offset by expansion during green condition and later on by maintaining original volume.

• Self-leveling by nature.

• Can withstand temperature up to 200ºC

• Easy placement and filling of under bases of machinery.

• Non-metallic and chloride free.

APPLICATION PROCEDURE

Surface Preparation:

• All contaminations fully removed by chemical or mechanical methods.

• All bolt pockets and under bases must be free from dust, laitance. If needed, substrate must be hacked to provide extra mechanical key.

• The pockets and under bases must be saturated with water to allow for full absorption for at least 24 hours. Just before the grouting is to commence, all water must be removed completely leaving the surface only damp.

Mixing: Mechanical mixing using a grout mixer or concrete mixer is recommended.

• Place 80% of the water required in a concrete mixer (100% water in case of a grout mixer).

• Slowly add the required amount of FLOWGROUT 40 while mixing continuously for 1 minute. Add balance quantity of water (20%) and mix for 3 to 5 minutes. This will provide a smooth even consistency of grout.

Placing:

• The mixed grout poured immediately from one side only to avoid air pockets.

• Grouting must be continuous until the cavity is completely filled to the desired level.

• All exposed areas must be restrained by covering with wooden plates or polythene sheets with sand sprinkled on top of the sheet.

Bolt Packets:

• Depending on the size of the bolt pockets, 50- 100% cleaned 10mm sound aggregates by weight of grout consumption may be sealed incorporated to economise on grout and also to keep the heat of hydration low.

Under base Plate:

• Leak proof strong formwork must be provided to withstand operational stresses while grouting and all edges must be sealed with FLOWGROUT 40 troweling consistency to arrest the grout flowing out of formwork.

Curing:

• Within 8 hours of grouting all grouted areas must be cured with wet hessian cloth or water pounding according to the temperature for a minimum 7 days period.

It can be used in bolt pockets and base plate grouting of all rotary and static equipment, crane, stanchion based and all types of machinery in all types of industrial projects.

PACKING

FLOWGROUT 40 is supplied in 25 Kg lined HDPE bags.