Although crystalline waterproofing technology has been around for more than 50 years, it is still considered “state-of-the-art” and has only recently been embraced by the construction industry as a superior replacement for conventional membranes. Used in virtually every country around the world, integral crystalline waterproofing has been repeatedly and successfully tested.

Crystalline waterproofing systems rely on a revolutionary crystalline technology that turns porous concrete into an impermeable barrier. The result is a structure with reduced cracking, self-sealing and waterproofing abilities which provides a powerful defence against water damage and corrosion of reinforcing steel.

Whether it is new construction, upgrading an existing structure or repairing cracks, this technology will help you build quality, reliability and cost-effectiveness into the concrete.

Crystalline Waterproofing Advantages

√ Replaces unreliable exterior membrane systems

√ Penetrates deep into concrete—many inches over time

√ Self-seals hairline cracks—minimum .5 mm (.02 in.)

√ Reactivates in the presence of moisture—even years later

√ Effective against hydrostatic pressure—up to 140 m (460 ft) of head pressure

√ Waterproofs from any direction (i.e. positive or negative side)

√ Impervious to physical damage and deterioration

√ Easy to apply and reduces potential for human error

How Does It Work?

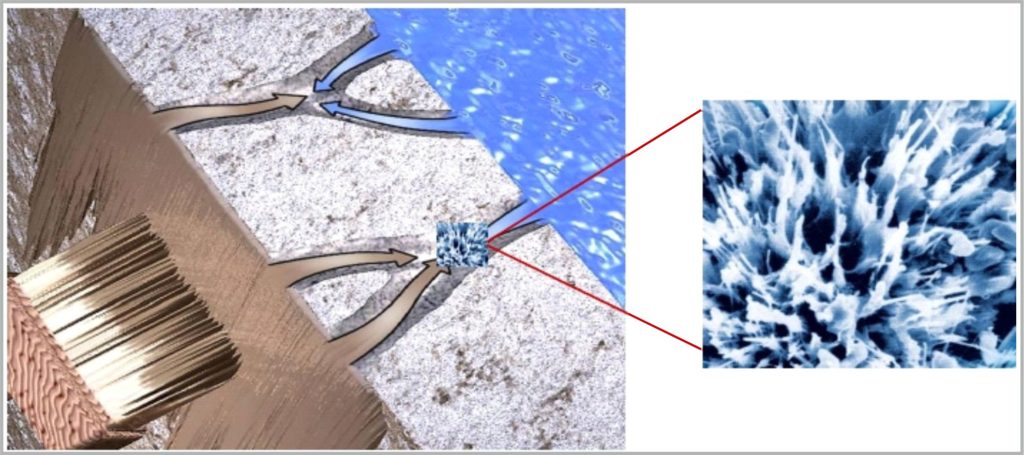

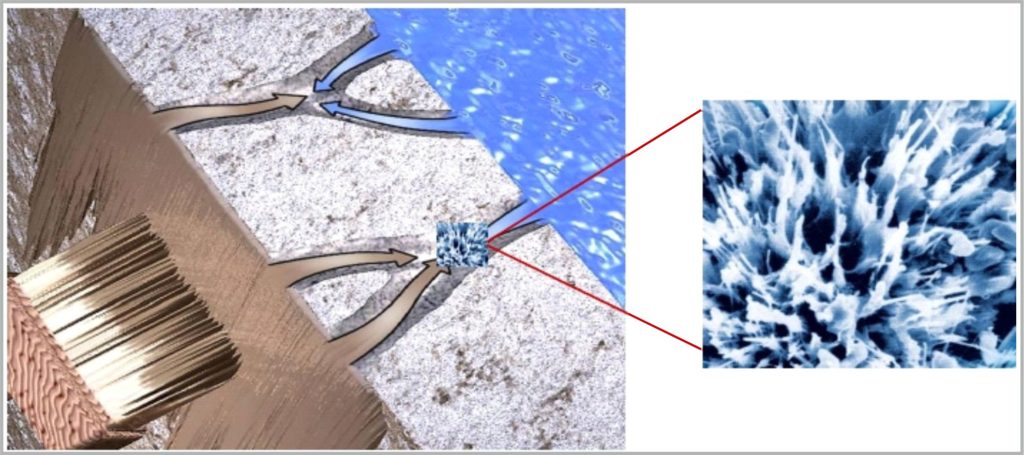

Unlike old-fashioned external membranes, which rely on an additional hurdle to shield the concrete from moisture, crystalline waterproofing product actually transforms the concrete into a water-resistant barrier. It becomes an integral part of the concrete matrix when applied to existing concrete or added to the mix at time of batching. When combined with water and concrete, the product reacts with un-hydrated cement particles to form millions of needle-like crystals. Over a period of weeks and months, these crystals grow, filling the naturally occurring pores and voids in concrete, and permanently blocking the pathways for water and waterborne contaminants.

Later, if cracks form due to settling or shrinkage, incoming water triggers the crystallization process and additional crystals begin to grow. The crystals fill the cracks and ensure that the structure’s waterproofing barrier is maintained and protected. In other words, the product has the unique ability – even years later – to self-seal hair-line cracks before they turn into costly cracks in your budget.

How are the Products applied?

Crystalline waterproofing products are supplied as a dry powder comprised of Portland cement, silica sand and special chemicals. For new construction it can be added to the concrete mixture at the plant or on-site; applied as a dry-shake and towelled into fresh concrete surfaces; or brush-applied in slurry form to existing concrete. In addition, the products can be used to repair concrete cracks and waterproof construction joints in grout (dry pack) form.

Where Is It Used?

Crystalline waterproofing products have proven their versatility in hundreds of projects across the globe. They have been incorporated in high-rise office towers, commercial buildings, parking structures, elevator pits, subway tunnels, and mountain pipelines. They have demonstrated their reliability in protecting water supply in reservoirs and treatment tanks, recreational facilities such as pools and spas and the supporting structures of bridges and dams. These products can provide permanent waterproofing in a wide range of applications and environmental conditions.

Crystalline Waterproofing will reduce cost!

Cost savings – materials

Savings can be realized immediately through the elimination of strengthening agents, water reducers, plasticiser, curing agents, air entrainers, set retarders and shrinkage compensators. One of the largest immediate savings is the elimination of external waterproofing membranes which require both the purchase of waterproofing membrane and labour costs.

Cost savings – Labour

The ability to increase pumping, pouring, finishing and cleaning efficiency through increased flow ability and ease of use will also provide immediate labour cost savings. This technology dramatically increases productivity by reducing the labour demands and increasing the speed of the construction.

Cost savings – Job

A few simple calculations can be utilized to determine the dramatic savings that can be realized through the elimination of additives and externally applied water proofing membranes. The simple use of one additive can actually increase productivity while reducing costs.

Cost savings – Repair

The simplicity in using crystalline waterproofing products also eliminates errors due to incompetence and neglect as it is applied directly to the ready mix truck or at the batching plant. When using these products with a ready mix truck, the required amount of is added and allowed to mix for 10 minutes. The concrete is then ready for pumping and placing. The ease of use will eliminate the inconvenient and costly necessity of repairing somebody’s mistake.

Cost savings – Long Term

The long term cost savings are extremely impressive. The ability of crystalline waterproofing products to strengthen a concrete structure, to permanently waterproof and to protect reinforcing steel from corrosion and pollution increases the life expectancy of concrete structures. This will reduce the need for costly repairs and restoration in the future. It is not difficult to understand the savings advantage that can be achieved in the long run through the simple addition of crystalline products to concrete. The savings include labour, equipment, materials, financing, and the opportunity costs involved when a repair, restoration or rebuilding of a structure is required.

Integral crystalline concrete waterproofing admixture – FAIRCRETE RMW CRYSTALLINE

This product eliminates the need for conventional external waterproofing membranes. It saves time, money and hassle at the construction site over the lifetime of the concrete. The crystalline admixture is available in pulpable bags for easy addition to the concrete mixer. It won the ‘Most Innovative Product’ award from the World of Concrete tradeshow. In addition, it is the first concrete admixture to be certified by the International Code Council – Evaluation Service (ICC-ES) as a Chemical Admixture used in Concrete (AC198). This chemical admixture is used for the treatment of concrete and concrete products to protect against water intrusion, leakage, cracking, chemical attack, and corrosion of reinforcing steel.

Specially designed chemical admixtures are available for waterproofing cementitious mortar. It contains a unique blend of chemicals that react with the cementitious materials in the mortar to form hydration crystals, blocking water intrusion.

Liquid, membrane-forming compounds are also available for curing concrete. The liquid helps to prevent the rapid evaporation of moisture from fresh concrete to allow more complete cement hydration and to dramatically reduce the occurrence of drying shrinkage cracks. It is water-based and is a suitable replacement for wet curing in conformance with ACI 308 guidelines.

Surface-Applied Concrete Waterproofing Products – WATERGUARD CRYSTALLINE

Recently built structures and heritage buildings need water protection too! Whether you’re waterproofing a new structure or repairing leaks, concrete waterproofing treatments allow you to turn existing concrete into a waterproof barrier reliably and cost-effectively.

Repair & Maintenance Systems – WATERGUARD T CRYSTALLINE

No matter how carefully you build and maintain your concrete structure, it’s not a matter of if cracks will occur, but when. At best, concrete cracks are an unattractive nuisance. At worst, they lead to leaks that can damage the interior of the building, corrode steel reinforcements, and ultimately shorten the life of the concrete structure.

Unlike other systems, the repair and maintenance products that are available, protects from any direction. Even against high water pressure. Because they can be applied to either side of the concrete, there are no limits when it comes to repairing or waterproofing hard or impossible to reach areas. These products can be put to work wherever the cracks are—without expensive, time consuming perimeter digging.

How does Crystalline Waterproofing Technology work?

This technology is an integral crystalline concrete waterproofing system that was developed over 30 years ago. When added or applied to concrete, crystalline chemicals cause long, narrow crystals to form. The crystals penetrate through the concrete and fill the pores and hairline cracks. The crystals continue to react with incoming water to self-seal cracks that inevitably develop in concrete over time. This technology protects concrete structures against water and contaminants that can weaken or destroy concrete and corrode steel reinforcements.

Where is it used (types of jobs)?

Crystalline waterproofing systems can benefit any concrete structure at risk of water penetration. Its self-sealing ability and resistance to high water pressure makes it ideally suited for below-grade foundations, parking lots, elevator pits, water containment and aquatic facilities, bridges, dams, tunnels, and pipelines. Integrated – Crystalline waterproofing penetrates into the concrete. It will not crack, peel, tear or wear-away.

Continually self-seals – Crystals within the concrete reactivate repeatedly over time to reseal cracks and prevent water penetration.

Environmental – The products are non-toxic, non-flammable and odorless. This allows the concrete to be recycled. Traditional membrane systems are petroleum-based. They use adhesives with highly volatile organic compounds. The vapor from these compounds can cause respiratory problems and contribute to “sick building syndrome”. Oil can also leach out and contaminate ground water.

Maximizes space – No additional space outside the structure is required for membrane application. This allows for a larger structural footprint and building right to the property line.

Saves time – The products can be applied to green concrete or added to the ready-mix truck. There is no need to wait for the membrane application, so backfilling can begin right away.

Tropical climates – Membrane systems become brittle and deteriorate when exposed to prolonged heat. Crystalline systems reduce premature moisture loss in hot or tropical climates. It creates a more durable structure and reduces shrinkage and cracking. It is unaffected by climate and remains effective for the life of the structure.

How is our crystalline technology different from other crystalline technologies?

Many products claim to have permanent waterproofing abilities. Most are only damp proofers and have little penetrating ability. These products contain stearates or sodium silicates. They waterproof by filling initial surface pores of concrete only. Therefore, they work well initially, but continually deteriorate over time.

Our products are free of stearates, sodium silicates and chlorides. It contains a proprietary blend of chemicals that cause hydration crystals to grow throughout the capillaries and pores of concrete as the material comes in contact with moisture. The crystals continue to react in the presence of later, making our products more effective with time.

For more details, Contact at Ph.: +91-265-2331193, WhatsApp : +91 7574834603 Toll Free: 1800 12345 34

Visit www.fairmate.com E-mail: enquiry@fairmate.net