Introducing FAIRFIX EPU: Your Ultimate Bonding Solution

In the world of adhesives, where strength, versatility, and innovation intersect, emerges the exceptional FAIRFIX EPU. This adhesive marvel takes the best of both worlds – epoxy and polyurethane – and blends them into a formidable bonding solution. So let’s take a closer look at what sets FAIRFIX EPU apart, while keeping its remarkable applications and benefits intact.

Discovering FAIRFIX EPU:

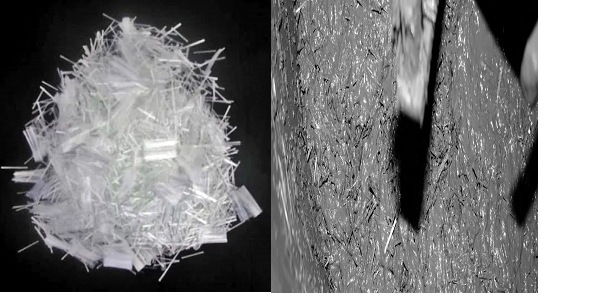

FAIRFIX EPU isn’t your ordinary adhesive; it’s a fusion of two adhesive powerhouses, epoxy and polyurethane. Epoxy provides unmatched bonding strength and resistance to chemicals, while polyurethane adds flexibility and the remarkable ability to adhere to a wide spectrum of materials.

Unveiling Its Power: Where It Excels: FAIRFIX EPU’s strength shines across various application domains:

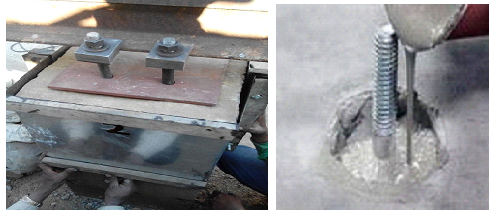

1. Construction Brilliance: It’s your go-to adhesive for securely bonding cement surfaces, drywall boards, both interior and exterior walls, and even floors – offering a solid foundation for architectural excellence.

2. Metal Fusion Expertise: When dealing with metals like iron, steel, and more, FAIRFIX EPU forges unbreakable connections, making it an essential tool for structural and artistic metalwork.

3. Concrete Confidence: As a combination of epoxy and polyurethane, it forms strong connections with both plain and reinforced concrete, making structures even stronger.

4. Versatility at Its Finest: Its impressive compatibility extends to a wide range of surfaces – from rubber and glass to wood and beyond – making it an adhesive of choice for various bonding scenarios.

Outstanding Advantages: The great qualities of FAIRFIX EPU keep on shining:

1. Strength Redefined: Merging the strength of epoxy and polyurethane, it creates strong, long-lasting bonds.

2. Flexibility and Toughness Combined: Stays tough yet flexible to accommodate movements without compromising the bond.

3. Unparalleled Versatility: Be it indoor or outdoor applications, on diverse surfaces like concrete or wood, FAIRFIX EPU adapts effortlessly.

4. Reliability in Concrete Bonding: When working with concrete, trust FAIRFIX EPU to enhance structural integrity and longevity.

5. Innovation Personified: FAIRFIX EPU showcases the amazing results from combining two powerful adhesives.