WATERGUARD LIQUID MEMBRANE

POLYMER MODIFIED BITUMEN BASED FIBER REINFORCED FLEXIBLE, LIQUID APPLIED WATERPROOFING MEMBRANE

WATERGUARD LIQUID MEMBRANE is polymer-modified water based on bitumen, liquid applied, fiber reinforced flexible, damp-proof, and vapor-proof liquid membrane. WATERGUARD LIQUID MEMBRANE is highly resistant to aggressive soils and soluble salts providing an effective continuous barrier and protection against water Bourne damage. If a water flood test is to be run, the membrane should cure for a minimum of 7 days. Whilst WATERGUARD LIQUID MEMBRANE is resistant to frost, adhesion will be impaired if applied to frosted substrates.

SALIENT FEATURES

• free from solvents

• Very low permeability

• High elasticity, ensuring a permanently flexible barrier over a wide range of temperatures

• Thermally stable – irreversible chemical cure eliminates melting and flow at high temperature

• Can be applied to a range of substrates

• Outstanding resistance to oxidation and brittlement

• Fibers improve tensile strength and abrasion resistance

APPLICATION PROCEDURE

Surface preparation: All substrates must be sound, clean, dry, smooth and free from protrusions, voids, honey-combs and high spots. Presence of curing agents, paint and oil will impair adhesion.

Moss and lichen must be removed and area treated with proprietary fungicidal wash to kill spores and inhibit further growth. Following treatment wash area thoroughly with clean water and allow drying. Fillets must be provided at corners or sharp angles using 4:1 sand and cement mortar modified with a good quality bonding agent – FAIRCRETE SB (L).

Priming: Priming is not normally required on good quality, well prepared substrates.

Cracks: All shrinkage and non-structural cracks must be treated with not less than 1.5mm coating of WATERGUARD LIQUID MEMBRANE extending 75mm either side of the crack. Allow to cure overnight prior to general application.

Application: WATERGUARD LIQUID MEMBRANE should be applied by brush to obtain a continuous unbroken film. Two coats are required with the second coat applied at right angles after the first coat has dried. WATERGUARD LIQUID MEMBRANE must be protected from mechanical damage during subsequent construction or backfilling works. Any damage may be repaired by spot application. Application should be avoided if substrate temperatures are below 5ºC or rain is imminent.

Curing: Allow each coat to dry a minimum of 24 hours before re-coating. full cure may take after 7 days of application or more depending on temperature conditions. Cold temperatures will slow cure time, higher temperature may speed up cure time.

WATERGUARD LIQUID MEMBRANE is particularly suitable for a wide range of applications including wet areas, foundations, basements, terraces, retaining walls, bridge abutments, planters, inverted roofs and remedial repairs to felt, asphalt, concrete, fibreous cement or other roof structures when protected from exposure to direct sunlight.

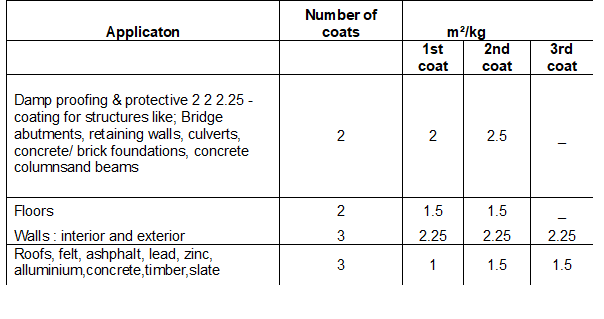

PACKING & COVERAGE

WATERGUARD LIQUID MEMBRANE is supplied in 20 kg pails. It has a coverage of 1.5 – 2 m² per kg at 1mm WFT.

Coverage rate will vary with substrate condition and profile.

Leave a Reply